The ignition system is a critical component in internal combustion engines that plays a crucial role in starting and powering the engine. It is responsible for generating the high-voltage electrical spark required to ignite the air-fuel mixture in the combustion chamber, leading to the combustion process and power generation. In this article, we will delve into the details of the ignition system, including its functions, types, components, working principle, and maintenance.

Functions of the Ignition System

The ignition system serves several important functions in an internal combustion engine:

- Ignition: The primary function of the ignition system is to provide a high-voltage electrical spark at the right time to ignite the air-fuel mixture in the combustion chamber. This results in the combustion of the fuel, which generates the force that powers the engine.

- Timing: The ignition system is responsible for precisely timing the ignition spark to occur at the optimal moment in the engine’s combustion cycle. This timing is critical for efficient combustion, smooth engine operation, and maximum power output.

- Control: The ignition system allows for the control of the ignition timing, which can be adjusted based on various engine operating conditions, such as engine speed, load, and temperature. This helps to optimize engine performance, fuel efficiency, and emissions.

Types of Ignition Systems

There are two main types of ignition systems used in modern internal combustion engines:

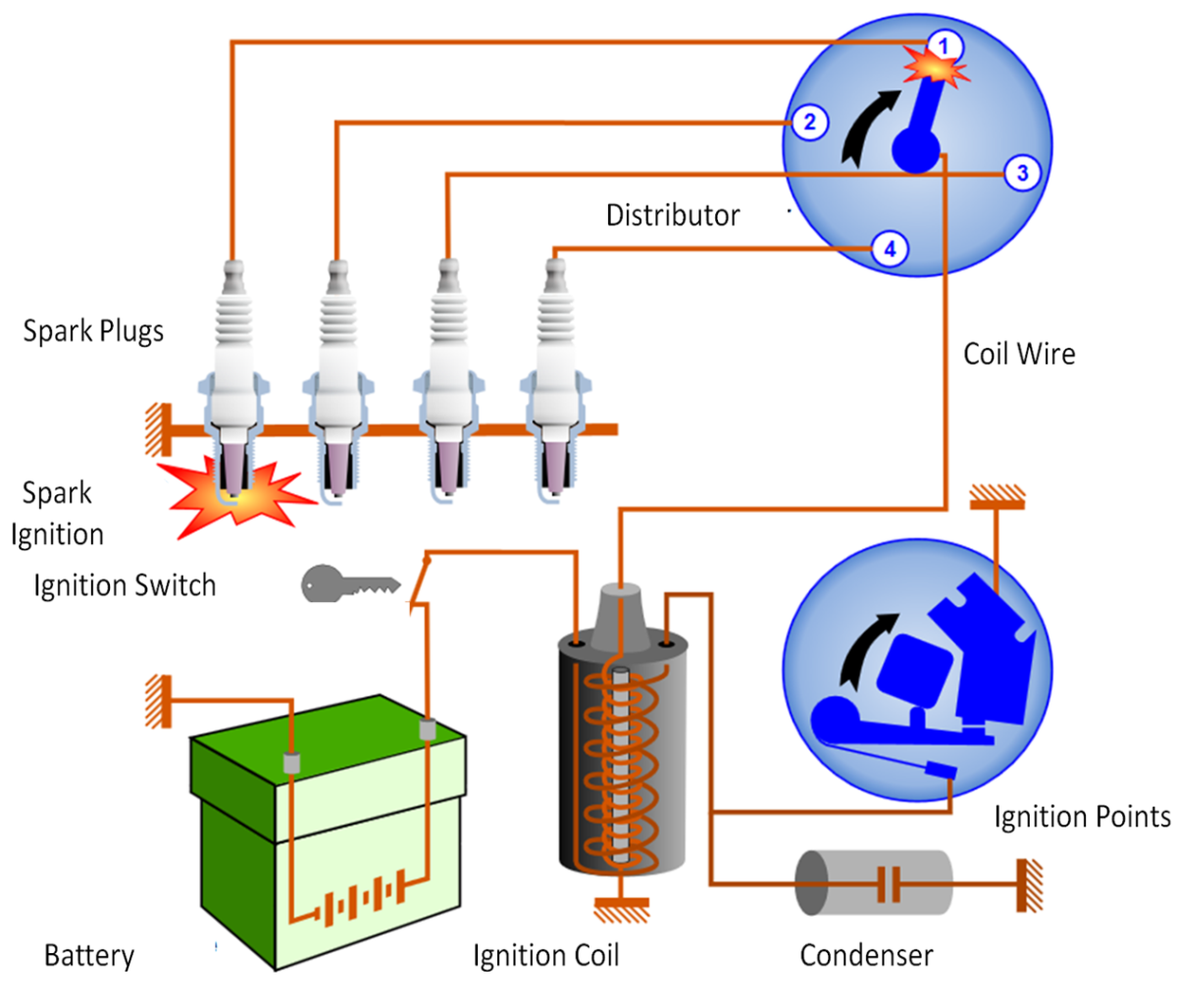

- Conventional Ignition System: Also known as the traditional or mechanical ignition system, this type of system uses a distributor, ignition coil, spark plugs, and spark plug wires to generate and distribute the high-voltage spark to each cylinder. The distributor is driven by the engine’s camshaft and uses mechanical components to control the timing and distribution of the spark.

- Electronic Ignition System: This type of system has replaced the conventional ignition system in most modern vehicles. It uses electronic components, such as sensors, an electronic control module (ECM), and individual ignition coils for each cylinder, to generate and control the ignition spark. Electronic ignition systems offer greater accuracy, reliability, and control over the ignition timing compared to conventional systems.

Components of the Ignition System

The ignition system is comprised of several key components that work together to generate and deliver the high-voltage spark to the spark plugs:

- Ignition Coil: The ignition coil is a transformer that converts the low-voltage electrical current from the battery into a high-voltage current needed to create the spark. It typically consists of a primary winding, a secondary winding, and a magnetic core.

- Spark Plugs: Spark plugs are threaded into the combustion chamber and are responsible for creating the spark that ignites the air-fuel mixture. They are designed to withstand the high heat and pressure inside the combustion chamber and must be replaced periodically as they wear out.

- Spark Plug Wires: Spark plug wires, also known as ignition cables or spark plug leads, are used to transmit the high-voltage electrical current from the ignition coil to the spark plugs. They are made of special high-resistance wire to prevent electrical interference and ensure proper spark plug firing.

- Distributor (in Conventional Ignition System): The distributor is a mechanical device used in conventional ignition systems to control the timing and distribution of the spark to each cylinder. It uses a rotating rotor and a cap with contact points or electronic sensors to determine the timing and sequence of the spark.

- Sensors (in Electronic Ignition System): Electronic ignition systems use various sensors, such as the crankshaft position sensor, camshaft position sensor, and engine coolant temperature sensor, to gather information about the engine’s operating conditions and control the ignition timing accordingly.

- Control Module (in Electronic Ignition System): The electronic control module, also known as the ignition control module or engine control module (ECM), is the brain of the electronic ignition system. It receives input from various sensors and uses this information to determine the optimal ignition timing for the engine. It also controls the operation of the ignition coils, ensuring that the spark is delivered to the correct spark plug at the right time.

Working Principle of the Ignition System

The ignition system works based on the principle of electromagnetic induction. When the ignition switch is turned on, it sends a low-voltage electrical current from the battery to the primary winding of the ignition coil. This current creates a magnetic field around the coil’s magnetic core. When the ignition control module or distributor (in a conventional ignition system) determines that the spark should be generated, it interrupts the current flow in the primary winding, causing the magnetic field to collapse suddenly. This rapid change in magnetic field induces a high-voltage current in the secondary winding of the ignition coil. This high-voltage current is then transmitted through the spark plug wires to the spark plugs, where it jumps across the spark plug gap, creating a spark that ignites the air-fuel mixture in the combustion chamber.

The ignition timing, or the precise moment when the spark is generated, is determined by the engine’s operating conditions, such as engine speed, load, and temperature. In a conventional ignition system, the distributor uses mechanical components, such as the camshaft and contact points, to determine the timing and distribution of the spark to each cylinder. In an electronic ignition system, sensors gather information about the engine’s operating conditions, which is then processed by the electronic control module to determine the optimal ignition timing. The ignition timing is continuously adjusted in real-time to ensure efficient combustion, smooth engine operation, and maximum power output.

Maintenance of the Ignition System

Proper maintenance of the ignition system is essential for ensuring reliable engine performance and extending the lifespan of ignition system components. Here are some important maintenance tasks for the ignition system:

- Regular Spark Plug Replacement: Spark plugs wear out over time and need to be replaced at the manufacturer-recommended intervals. Worn spark plugs can cause misfires, reduced fuel efficiency, and increased emissions. It’s important to use the correct type and heat range of spark plugs for your specific engine to ensure optimal performance.

- Spark Plug Wire Inspection: Spark plug wires can degrade over time due to heat, moisture, and wear. Inspect the spark plug wires regularly for signs of damage, such as cracks, fraying, or corrosion, and replace them if necessary.

- Ignition Coil Inspection: Ignition coils can fail due to heat, electrical overload, or age. Inspect the ignition coils for signs of damage, such as cracks, corrosion, or other visible defects. If any issues are detected, replace the faulty ignition coil promptly.

- Distributor Cap and Rotor (in Conventional Ignition System): If your vehicle has a conventional ignition system with a distributor, regular inspection and replacement of the distributor cap and rotor may be necessary. These components can wear out over time and affect the timing and distribution of the spark.

- Sensor Inspection and Cleaning (in Electronic Ignition System): In an electronic ignition system, sensors play a crucial role in determining the ignition timing. Regular inspection and cleaning of the sensors, such as the crankshaft position sensor and camshaft position sensor, can help ensure accurate sensor readings and optimal ignition timing.

- Check for Loose Connections: Loose or corroded connections in the ignition system can cause poor electrical conductivity and affect the performance of the ignition system. Regularly check for loose or corroded connections in the ignition coil, spark plug wires, distributor (if applicable), and sensors (if applicable), and clean or tighten them as needed.

- Follow Manufacturer’s Maintenance Recommendations: It’s crucial to follow the manufacturer’s maintenance recommendations for your specific vehicle when it comes to the ignition system. The manufacturer’s recommendations are based on extensive research and testing to ensure optimal performance and longevity of the ignition system components. These recommendations may include specific intervals for spark plug replacement, inspection of ignition system components, and other maintenance tasks. Following these recommendations can help prevent potential issues and keep your ignition system in top condition.

- Use High-Quality Components: When replacing ignition system components, it’s important to use high-quality components that meet or exceed the manufacturer’s specifications. Cheap or low-quality components may not provide reliable performance and can result in issues such as misfires, reduced fuel efficiency, and increased emissions. Investing in high-quality components can help ensure the longevity and performance of your ignition system.

- Keep the Ignition System Clean: A clean ignition system is essential for optimal performance. Accumulated dirt, debris, and grease can affect the performance of ignition system components, such as spark plugs and sensors. Regularly clean the ignition system components, including spark plugs, spark plug wires, distributor cap and rotor (if applicable), and sensors (if applicable), to prevent any build-up that may affect their performance.

- Avoid Overloading the Ignition System: Overloading the ignition system can lead to premature wear and failure of ignition system components. Avoid overloading the ignition system by avoiding excessive cranking of the engine, prolonged idling, or unnecessary high-revving. Additionally, avoid adding any unnecessary electrical loads to the vehicle’s electrical system, as it can put extra strain on the ignition system.

- Pay Attention to Warning Signs: It’s important to pay attention to any warning signs that may indicate issues with the ignition system. Signs such as rough idle, engine misfires, difficulty starting the engine, reduced fuel efficiency, and increased emissions may indicate problems with the ignition system. If you notice any of these signs, it’s essential to address them promptly to prevent further damage to the ignition system and the engine.

- Consult a Professional Mechanic: If you’re not familiar with the intricacies of the ignition system or if you’re experiencing issues that you’re unable to diagnose or repair on your own, it’s best to consult a professional mechanic. A qualified mechanic can accurately diagnose and repair any issues with the ignition system, ensuring that it’s functioning optimally.

The ignition system is a critical component of a vehicle’s engine, responsible for generating the spark that ignites the air-fuel mixture in the combustion chamber. It ensures proper combustion, smooth engine operation, and maximum power output. Ignition systems have evolved from conventional systems with mechanical components to modern electronic systems that use sensors and electronic control modules for precise timing and distribution of the spark.

Regular maintenance of the ignition system, including spark plug replacement, spark plug wire inspection, ignition coil inspection, distributor cap and rotor inspection (if applicable), sensor inspection and cleaning (if applicable), and following the manufacturer’s maintenance recommendations, is essential for optimal performance and longevity of the ignition system components. Using high-quality components, keeping the ignition system clean, avoiding overloading the system, paying attention to warning signs, and seeking professional help when needed are also important for ensuring reliable ignition system performance.

By understanding the working principle of the ignition system, performing regular maintenance, and addressing any issues promptly, you can ensure that your vehicle’s ignition system operates optimally, leading to reliable engine performance and a smooth driving experience.

Whether you are a DIY enthusiast or prefer to rely on professional mechanics for maintenance and repairs, taking care of your vehicle’s ignition system is crucial for the overall performance and longevity of your engine. Ignition system issues can lead to reduced fuel efficiency, increased emissions, rough idle, misfires, and even engine damage if not addressed promptly. Therefore, understanding the importance of the ignition system and following proper maintenance practices is essential for keeping your vehicle running smoothly.

In conclusion, the ignition system is a critical component of a vehicle’s engine that plays a crucial role in starting the engine and ensuring proper combustion of the air-fuel mixture. It has evolved from conventional mechanical systems to modern electronic systems, and regular maintenance is key to its optimal performance. By following the manufacturer’s recommendations, using high-quality components, keeping the ignition system clean, avoiding overloading, paying attention to warning signs, and seeking professional help when needed, you can ensure reliable and efficient ignition system performance, leading to a smooth driving experience and a well-maintained vehicle. Proper care of the ignition system is an investment in the longevity and performance of your vehicle’s engine, and it’s worth the time and effort to ensure its optimal functioning.